Search results for: 'Variable-speed drive solutions'

12

Results

in category

Products

Module

The HFI-MM kit (HYDAC Frequency Inverter Motor-Mounted Kit) is a mounted, tested and adjusted set of components consisting of an asynchronous motor and a drive controller.<br />The HFI-MM kit is a ready-to-use, speed-controlled asynchronous motor that does not require a control cabinet for the drive controller/frequency inverter.<br />Performance class up to 22 kW<br />

Product category

Variable-speed drive solutions control the drive motor so that kinetic energy is provided according to requirements. <br />The drive controller with its three-phase motor is the core of variable-speed drive solutions. This controller either powers a hydraulic system or the spindle drive of an electromechanical cylinder.<br />This technology makes extensive customisation of traditional hydraulic systems possible and, through this, achieve efficiency, such as: Reduced power and cooling requirements, lower tank and oil volumes, less material and lower weight.<br />Be it electromechanical cylinders or hydraulic systems: Variable-speed drives make it possible to network drive systems and make control tasks, commissioning and troubleshooting significantly easier.<br />

Product category

The HFI-MM (HYDAC Frequency Inverter - Motor Mounted) drive controller is a frequency inverter for three-phase asynchronous motors for speed control.<br />Its key advantage is that it can be attached directly to the asynchronous motor like a backpack. This means there is no need for a control cabinet and fewer tasks need to be performed on electrical systems. The advantages of a variable-speed asynchronous motor are retained.<br />This drive controller is available in performance classes from 0.55 kW to 22 kW<p> </p>

Product category

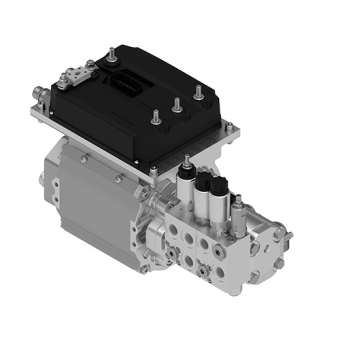

The new HYDAC EcoPack is a power unit product portfolio with variable-speed drive as a decentralised stand-alone solution, for supplying hydraulic actuators individually as needed. Depending on the duty cycle, the function and the supply voltage on the machine, we supply the EcoPack with an air- or a water-cooled motor in a voltage range of 24–400 VDC. The motor’s variable-speed functionality is realised by a speed transmitter communicating with the inverter. Furthermore, the inverter can be integrated into the machine’s CAN bus system (CANopen or SAE1939). In conjunction with HYDAC controllers (TTC), the EcoPack can also be incorporated into the machine architecture as a stand-alone system with its own controller.

0

Result

in category

Topics & Solutions

0

Result

in category

Downloads

Is your file not listed?

To our download & media center